DURABILITY FATIGUE TESTING

MEDICAL IMPLANT MECHANICS provides dynamic and static test machines, fatigue test machines, and valve durability testers. We continue to provide world-class, high-quality testing services.

MIM provides support for R&D needs in the areas of simulated use and durability thus providing product confidence before prototyping.

DESIGN OPTIMIZATION AND EVALUATION

FEA technology in design optimization, risk assessment of product research, and development has a unique advantage for the environment and the test conditions. By simulation analysis, MEDICAL IMPLANT MECHANICS can obtain the weak links of the structure and shorten the development time, improve product quality, and reduce development costs.

-

Heart Valve

-

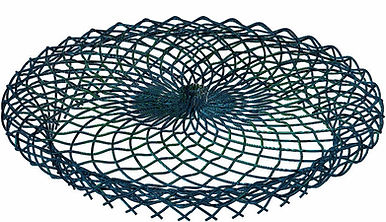

Stents

-

Filters

IMPLANT DEVICES

CORROSION TESTING OF MEDICAL IMPLANTS

MEDICAL IMPLANT MECHANICS provides cyclic potentiodynamic polarization testing per ASTM F2129 to determine the corrosion susceptibility of implantable medical devices. The test is conducted in body temperature (37°C) water bath using Princeton Applied Research 263A Potentiostat.

MIM performs corrosion tests on implantable medical devices to assess the potential pitting, crevice, galvanic or fretting effects caused by the device design.